ABOUT Techno Plas

We believe that doing business should be easy and for over 33 years our customers have depended on us to deliver whilst still looking for new and innovative ways to help them.

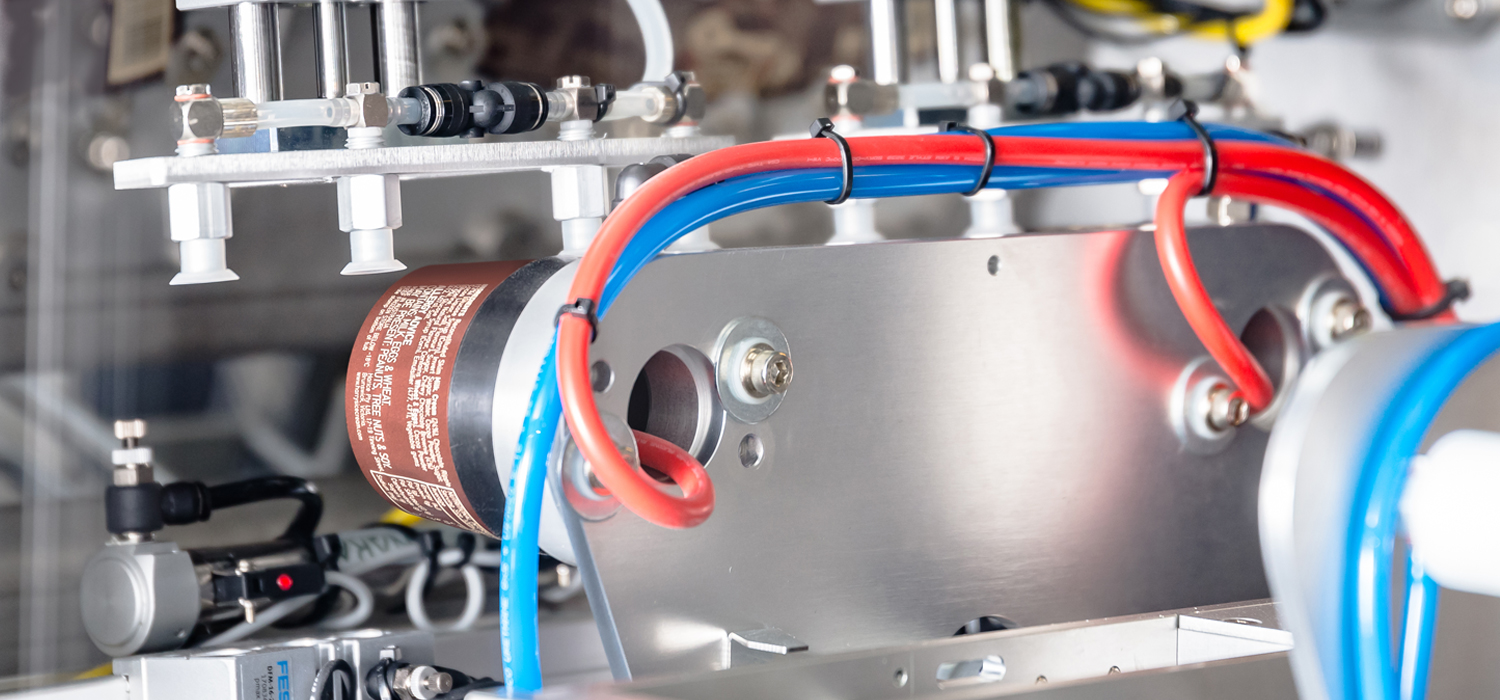

Advanced manufacturing gives unrivalled product performance, certainty of supply and since we run 24/7, affordability.

Our ultra clean and accredited factory can supply you with plastic consumer packaging using the latest developments in In-Mould Labelling and Laboratory plastic consumables manufacturing.

And, if we sell it, we made it in Australia.

IN-MOULD LABELLNG (IML) PACKAGING

We have spent years continuously developing our world class laboratory / medical moulding facility with filtered and pressurised air supply, to create an exceptional HACCP accredited packaging environment, specialising in plastic food packaging.

We work with you, to help represent your products using the world leading In-Mould Labelling (IML) techniques.

Our years of experience means you can order what you need for the short to medium term whilst our advanced manufacturing process keeps it affordable.

We care about the outside of the packaging as much as you care about what’s inside.

With over 33 years of industry leading experience, Techno Plas is fully Australian owned and operated

Reliable

43 moulding machines that run 24hrs a day, 7 days a week, despatching to locations all over the globe

Flexible

On-site product design, project management, flexible runs and manufacturing product any day or time of the week

Innovative

We always look for news ways to enhance our customers products and believe in working together to grow together

Warehousing

Our huge warehousing capacity means we can partner with you to reduce lead times

Products

Techno Plas offers a wide range of products with the following benefits

- Manufactured from approved Food Grade plastics

- IML (In Mould Labeling) capabilities

- Freezer grade options available

- Hot fill capabilities

- Tamperproof lids

- In house product design

Frozen (Ice Creams & Yogurts)

Our range of freezer grade, shatter resistant, tubs and lids are ideally suited to Ice-creams and yogurts, They include product sizes from individual portion(with spoon) to 1000ml specialty ice-cream tubs.

Ambient

Our total product range is suited to ambient temperature and a number of our products are also capable of supporting warm fill product.

Mix and match container colours and IML labelling to maximise your packaging impact.

Refrigerated (Dips, Sauces, Pate)

Our refrigerated products are all tamperproof and made of Food Grade Polypropylene with a clarity that will maximise the visual impact of your product and flexibility to ensure an exceptional seal.

Food Quality and Testing

Visit our laboratory/medical site via the attached link to see our extensive range of laboratory product for your food quality and testing needs.

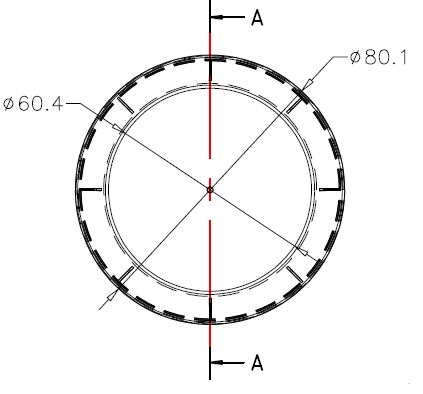

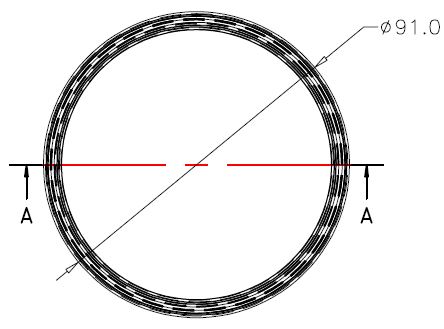

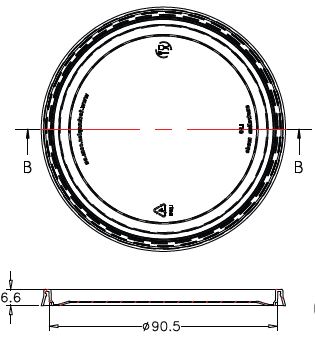

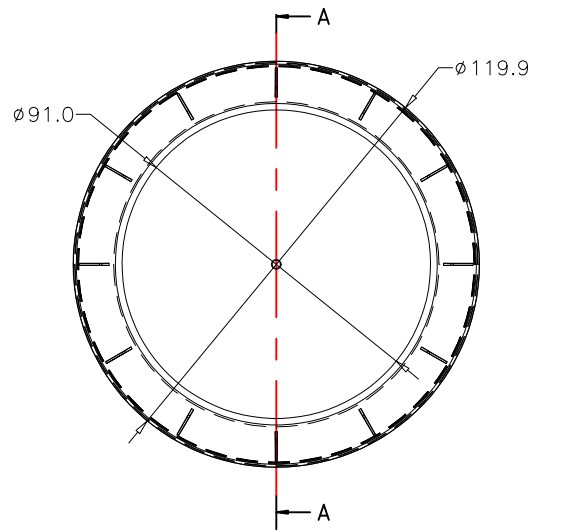

Standard Product Range

| Shape | Round | ||

|---|---|---|---|

| Container Options | Tub T93 P135 |

Closure Plug Fit |

Seal High Integrity |

| Weight | Lid without Tub 4.324gm |

||

| Shape | Round | ||

|---|---|---|---|

| Container Options |

Tub T110FS T133FS T137FS T150FS T180FS T230FS |

Closure Over Cap |

Seal N/A |

| Weight | Lid without Spoon 3.969gm |

Lid with Spoon 1.450gm |

Spoon 5.419gm |

| Shape | Round | ||

|---|---|---|---|

| Container Options |

Tub |

Closure Over Cap |

Seal N/A |

| Weight | Lid without Tub 2.5g |

||

| Shape | Round | ||

|---|---|---|---|

| Container Options |

Tub T520 |

Closure Plug Fit |

Seal Medium Integrity |

| Weight | Lid without Tub 5.186gm |

||

| Shape | Round | ||

|---|---|---|---|

| Container Options |

Tub |

Closure Plug Fit |

Seal High Integrity |

| Weight | Lid without Tub 3.969gm |

||

| Shape | Round | ||

|---|---|---|---|

| Container Options |

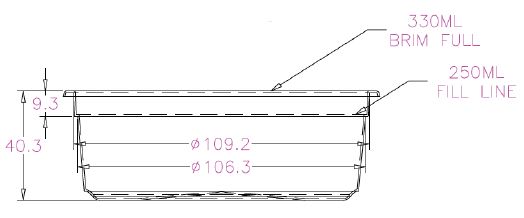

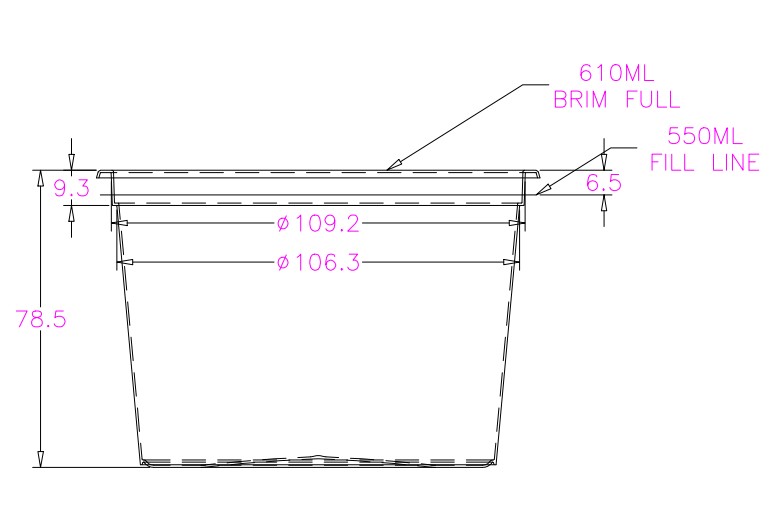

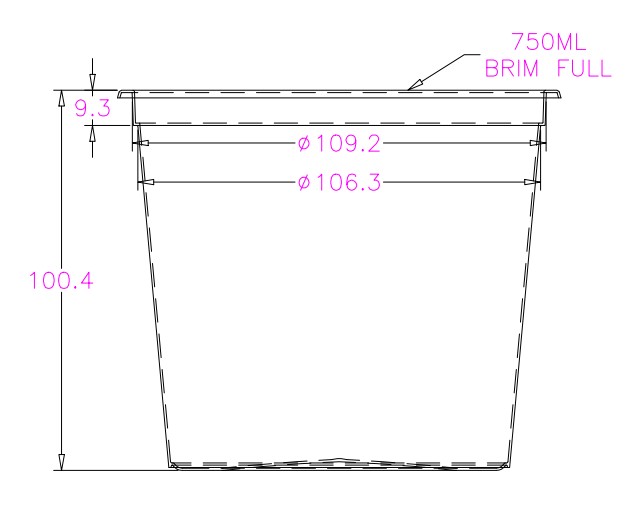

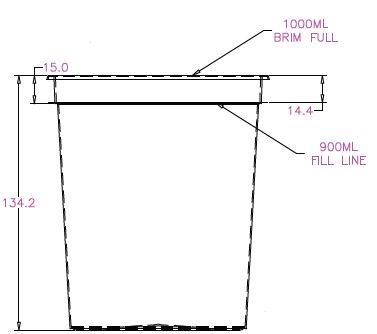

Tub T330 T610 T680 T750 T1000 |

Closure Over cap |

Seal N/A |

| Weight | Lid without Tub 8.49gm |

||

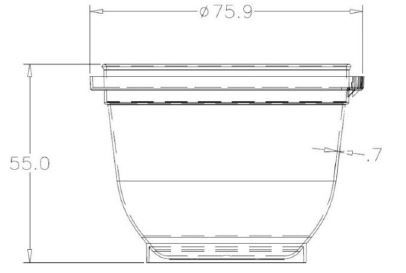

| Shape | Round curved | ||

|---|---|---|---|

| Tamper Evidence | Tamper evidence break-out tab (designed to stay attached to container) | ||

| Lid Options | Lid L72 |

Closure Plug Fit |

Seal High Integrity |

| Weight | Tub without Lid 9.035gm |

Tub with Lid 13.377gm |

|

| Shape | Round curved | ||

|---|---|---|---|

| Tamper Evidence | Tamper evidence break-out tab (designed to stay attached to container) | ||

| Lid Options | Lid L99 |

Closure Plug Fit |

Seal High Integrity |

| Weight | Tub without Lid 13.485gm |

Tub with Lid 20.666gm |

|

| Shape | Round tapered | ||

|---|---|---|---|

| Tamper Evidence | Tamper evidence break-out tab (designed to stay attached to container) | ||

| Lid Options | Lid L72 |

Closure Plug Fit |

Seal High Integrity |

| Weight | Tub without Lid 7.423gm |

Tub with Lid 11.765gm |

|

| Shape | Round tapered | ||

|---|---|---|---|

| Tamper Evidence | Tamper evidence break-out tab (designed to stay attached to container) | ||

| Lid Options | Lid L99 |

Closure Plug Fit |

Seal High Integrity |

| Weight | Tub without Lid 11.403gm |

Tub with Lid 18.584gm |

|

| Shape | Round tapered | ||

|---|---|---|---|

| Tamper Evidence | Tamper evidence break-out tab (designed to stay attached to container) | ||

| Lid Options | Lid L99 |

Closure Plug Fit |

Seal High Integrity |

| Weight | Tub without Lid 13.4gm |

Tub with Lid 20.6gm |

|

| Shape | Round tapered | ||

|---|---|---|---|

| Tamper Evidence | Tamper evidence break-out tab (designed to stay attached to container) | ||

| Lid Options | Lid L99 |

Closure Plug Fit |

Seal High Integrity |

| Weight | Tub without Lid 12.734gm |

Tub with Lid 19.915gm |

|

| Shape | Round tapered | ||

|---|---|---|---|

| Tamper Evidence | Tamper evidence break-out tab (designed to stay attached to container) | ||

| Lid Options | Lid L99 |

Closure Plug Fit |

Seal High Integrity |

| Weight | Tub without Lid 15.88gm |

Tub with Lid 23.06gm |

|

| Shape | Round tapered | ||

|---|---|---|---|

| Tamper Evidence | Tamper evidence break-out tab (designed to be removed from container) | ||

| Lid Options | Lid L94 |

Closure Plug Fit |

Seal Medium Integrity |

| Weight | Tub without Lid 18.8gm |

Tub with Lid 23.99gm |

|

| Shape | Round tapered | ||

|---|---|---|---|

| Tamper Evidence | Tamper evidence break-out tab (designed to stay attached to container) | ||

| Lid Options | Lid L99 |

Closure Plug Fit |

Seal High Integrity |

| Weight | Tub without Lid 18.69gm |

Tub with Lid 25.87gm |

|

| Shape | Round tapered | ||

|---|---|---|---|

| Tamper Evidence | Tamper evidence break-out tab (designed to be removed from container) | ||

| Lid Options | Lid L94 |

Closure Plug Fit |

Seal Medium Integrity |

| Weight | Tub without Lid 23.90gm |

Tub with Lid 29.086gm |

|

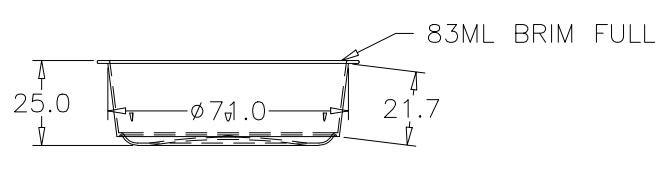

| Shape | Round tapered | ||

|---|---|---|---|

| Tamper Evidence | Foil Seal capable | ||

| Lid Options | Lid L77 |

Closure Over Cap |

Seal N/A |

| Weight | Tub without Lid 5.2gm |

||

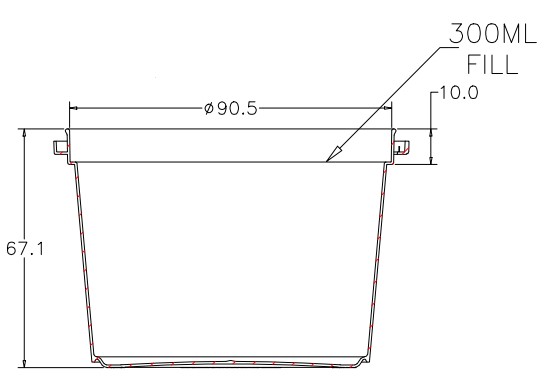

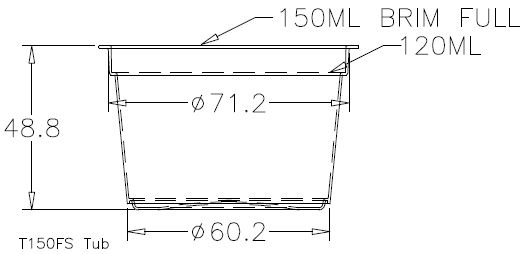

| Shape | Round tapered | ||

|---|---|---|---|

| Tamper Evidence | Foil Seal capable | ||

| Lid Options | Lid L77 |

Closure Over Cap |

Seal N/A |

| Weight | Tub without Lid 6.745gm |

Tub with Lid and Spoon 12.164gm |

|

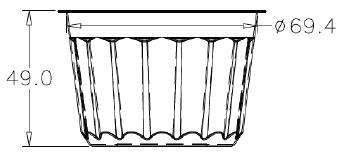

| Shape | Round tapered | ||

|---|---|---|---|

| Tamper Evidence | Foil Seal capable | ||

| Lid Options | Lid L77 |

Closure Over Cap |

Seal N/A |

| Weight | Tub without Lid 5.15gm |

||

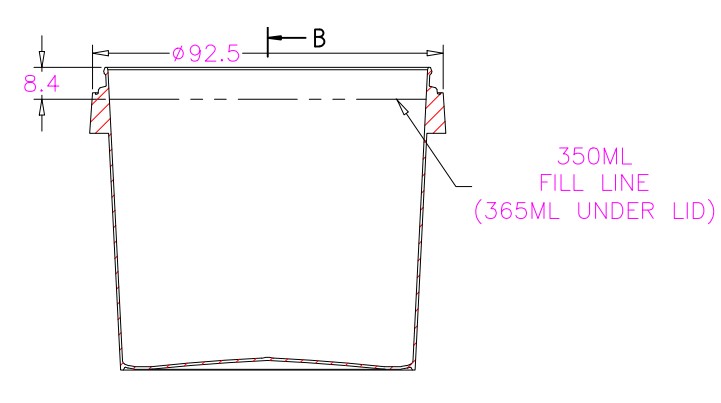

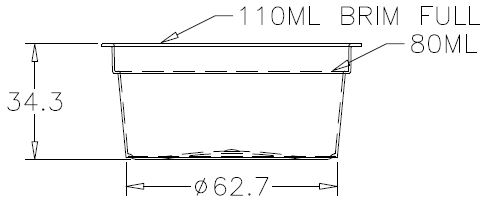

| Shape | Round tapered | ||

|---|---|---|---|

| Tamper Evidence | Foil Seal capable | ||

| Lid Options | Lid L77 |

Closure Over Cap |

Seal N/A |

| Weight | Tub without Lid 7.128gm |

||

| Shape | Round tapered | ||

|---|---|---|---|

| Tamper Evidence | Foil Seal capable | ||

| Lid Options | Lid N/A |

Closure N/A |

Seal N/A |

| Weight | Tub 6g |

||

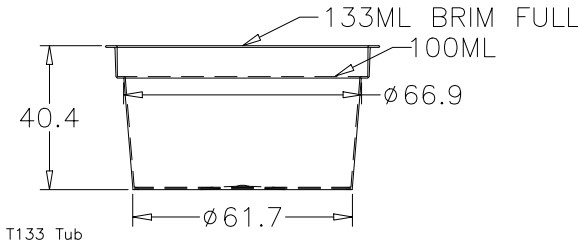

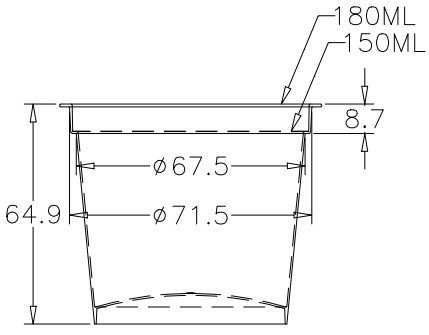

| Shape | Round tapered | ||

|---|---|---|---|

| Tamper Evidence | Foil Seal capable | ||

| Lid Options | Lid L77 |

Closure Over Cap |

Seal N/A |

| Weight | Tub without Lid 7.721gm |

Tub with Lid and Spoon 13.140gm |

|

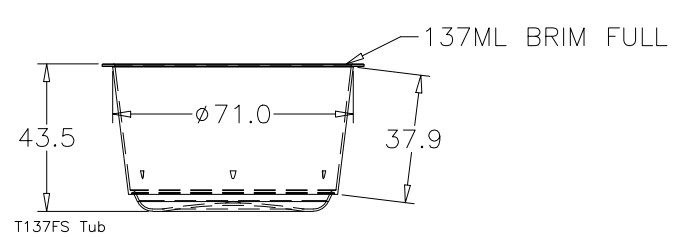

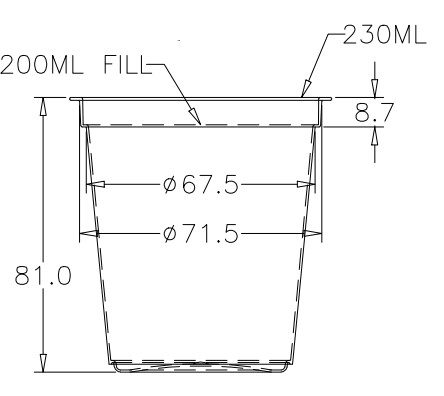

| Shape | Round tapered | ||

|---|---|---|---|

| Tamper Evidence | Foil Seal capable | ||

| Lid Options | Lid L77 |

Closure Over Cap |

Seal N/A |

| Weight | Tub without Lid 8.654gm |

||

| Shape | Round tapered | ||

|---|---|---|---|

| Tamper Evidence | Foil Seal capable | ||

| Lid Options | Lid L77 |

Closure Over Cap |

Seal N/A |

| Weight | Tub without Lid 9.25gm |

||

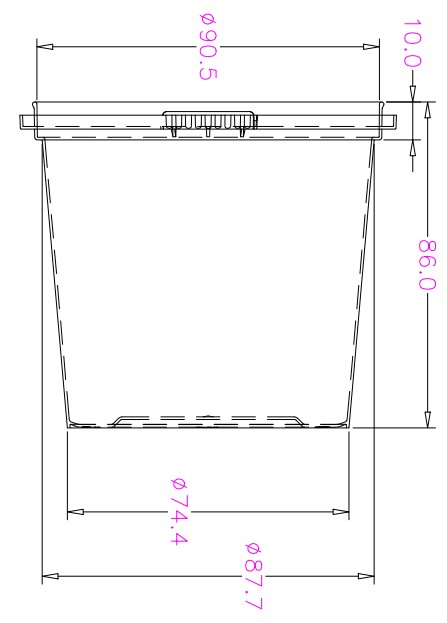

| Shape | Round tapered | ||

|---|---|---|---|

| Tamper Evidence | Foil Seal capable | ||

| Lid Options | Lid L117 |

Closure Over Cap |

Seal N/A |

| Weight | Tub without Lid 13.5g |

||

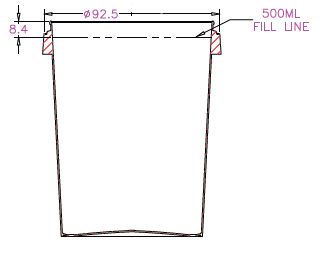

| Shape | Round tapered | ||

|---|---|---|---|

| Tamper Evidence | Foil Seal capable | ||

| Lid Options | Lid L117 |

Closure Over Cap |

Seal N/A |

| Weight | Tub without Lid 19gm |

||

| Shape | Round tapered | ||

|---|---|---|---|

| Tamper Evidence | Foil Seal capable | ||

| Lid Options | Lid L117 |

Closure Over Cap |

Seal N/A |

| Weight | Tub without Lid 22.05gm |

||

| Shape | Round tapered | ||

|---|---|---|---|

| Tamper Evidence | Foil Seal capable | ||

| Lid Options | Lid L117 |

Closure Over Cap |

Seal N/A |

| Weight | Tub without Lid 22.07gm |

||

| Shape | Round tapered | ||

|---|---|---|---|

| Tamper Evidence | Foil Seal capable | ||

| Lid Options | Lid L117 |

Closure Over Cap |

Seal N/A |

| Weight | Tub without Lid 32.4g |

||

Food Packaging in all shaped and sizes

With a state of the art facility and technology Techno Plas can work with you to customise and develop packaging suitable for your needs. Contact us today to find out how we can help stream-line your packaging processes.

IML Packaging

WHAT IS IML?

One of the challenges of traditional labelling techniques is creating a consistent and quality end product. Bubbles, wrinkles and crooked labels affect the overall look and success of the product on the shelf.

IML or “In Mould Labelling”, is an advanced manufacturing system bringing plastic moulding and labelling steps together in one seamless process creating a consistently high quality package for your product.

Preprinted labels are robotically placed into a mould of your tubs shape. Molten polypropylene is then injected into the mould to the form shape of your tub. The label fuses with the newly formed tub and emerges as a fully formed and labelled product.

WHY USE IML?

- Consistent Print Quality and Feel – High resolution imaging is used to present your product and your brand to an exceptionally high standard.

- Innovative – It’s possible to use advanced techniques to make your products stand out. It’s now possible to create a textured feel to the label to add a sensory sensation, use foil to add a touch of class or potentially dual-sided labels.

- Flexibility – Label production techniques and speed of label changes allows for lower label stocks and shorter run sizes.

- Reduced Production Costs – A two stage process of tub production & labelling becomes one seamless process, saving time and eliminating double handling, scheduling, storage and manufacture costs.

- Tough and Hygienic – Bubbles, wrinkles and crooked labels are a thing of the past. 100% resistant to moisture and humidity IML is ideally suited to frozen or refrigerated products amongst other uses.

- 100% Recyclable – both the package and label are of the same recyclable material, unlike combined paper and plastic or waxed cardboard options.

![Service | Innovation | Results [FOOD] Service | Innovation | Results [FOOD]](https://technoplasfoodpack.com.au/wp-content/uploads/2017/03/logo.png)